Andreas Marcus Maier

General Manager

Tools made of solid carbide, PCD, CBN and Cermet

HAM manufactures precision tools from solid carbide, PCD, CBN and Cermet.

HAM offers industrial customers a wide range of tools for drilling, milling, countersinking and reaming in both standardized and drawing-based designs for all machining applications.

We supply the right tool for your productivity increase. We offer you complete solutions from one source from standard tools to special tools according to drawings. Benefit from our many years of experience, our flexibility and speed.

Find the right solution for your machining applications in our standard program. This includes a wide range of solid carbide tools for drilling, countersinking, reaming and milling. Many of our catalog tools are available from stock.

We will be pleased to manufacture other intermediate dimensions or inch dimensions for you on request.

You can also benefit from our special polishing process for optimum chip removal and a reduction of built-up edges. Many of our catalog tools are available from stock with this special polishing process.

In our online catalog you will find our twist drills, Superdrill and Nirodrill, solid carbide deep hole drills, special drills, reamers, end mills, roughing mills, torus mills, radius mills and special milling cutters.

We would also be pleased to advise you on our product range.

SOLID CARBIDE SPECIAL TOOLS

We are happy to produce special tools made of solid carbide, cermet, PCD and CBN for your special application.

The requirements in modern machining technology are becoming more and more demanding. Due to our many years of experience in the manufacture of precision tools, we are well equipped for this.

We also have innovative and efficient solutions for the machining of modern materials. Benefit from our many years of experience and fast delivery times.

We are looking forward to your inquiry.

POLYCRYSTALLINE DIAMOND TOOLS ( PCD)

With highly qualified specialists and experienced employees as well as modern machinery, HAM is well equipped to manufacture complex tools from polycrystalline diamond (PCD). The use of these tools not only allows production at higher cutting speeds, but also increases tool life and surface quality many times over.

Our consulting expertise ensures the correct application and optimum performance of our tools.

Petra Eberle

General Manager

Tools for dental and medical technology

Specially developed working instruments are in use in every field of medicine.

HAM produces for the dental implant drill sector and for orthopedics and surgery various bone drills and countersinks as well as bone mills and rose drills according to customer requirements with corresponding functional and design requirements.

Our solid carbide radius and torus cutters are successfully used for CAD/CAM-supported production in the field of dental technology.

Here you can find our flyers on the topics

Andreas Marcus Maier

General Manager

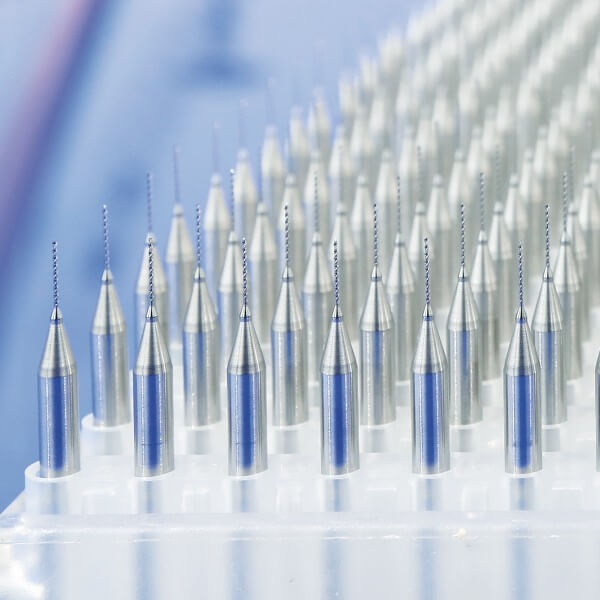

Tools for the printed circuit board industry

Multilayer or rigid-flexible printed circuit boards, with partially filled base materials, place particularly high demands on processing.

HAM meets these requirements effectively and economically with drills and cutters made of solid carbide.

When selecting the material manufacturers, only the best in the industry are considered: long-term partners with whom there is no need to discuss quality. The best products are the result of such cooperation.

State-of-the-art process engineering and comprehensive measuring and testing procedures guarantee products of the highest quality. For a long service life of the drill bit and consistent drill hole quality.

By using our tool management systems in the customer’s production, we ensure the availability of the tools 24/7.

Our systems organize all spare and production tools around the production.